In the world of industrial 3D printing, there really is a revolution going on! And it’s a tremendously exciting one, changing entire industries along the way. There’s a good chance it will impact your business in some way, whether it’s how you approach R&D, how you manufacture goods, how you approach distribution, or in some other way. The 3D printing industry is changing everything, and there’s data to back up that assertion—let’s take a look.

In the world of industrial 3D printing, there really is a revolution going on! And it’s a tremendously exciting one, changing entire industries along the way. There’s a good chance it will impact your business in some way, whether it’s how you approach R&D, how you manufacture goods, how you approach distribution, or in some other way. The 3D printing industry is changing everything, and there’s data to back up that assertion—let’s take a look.

An In-Depth Look at the 3D Printing Industry Today

3D printing (or additive manufacturing) has existed in some capacity since the 1980s and, until recently, was primarily used for rapid prototyping. Today, the capabilities of the technology are vast—and expanding by the minute. In the commercial space, 3D printing can surpass simple prototyping by printing final products (or parts) on demand using specialized materials ranging from metals to living cells.

There are many success stories. For example, 98 percent of the world’s hearing aids are produced using this method. However, In some instances, the process has been difficult to scale. The common perception is that large 3D printers on the market can seem expensive, slow, and/or difficult to use. New advances are being made, however, that make the technology more accessible to businesses. Let’s explore.

What’s Next for 3D Printing?

By definition, 3D printing has always brought agility to the design process and made product iterations more rapid. Today, 3D printing does this on a much larger scale and with much more to offer, leaving the industry at an inflection point. In fact, a recent report published by the Consumer Technology Association (CTA) and the United Parcel Service (UPS) projected the 3D printing market to triple in revenue over the next four years to a value of $21 billion (See Figure 1 below).

Figure 1. Source: 3D Printing: The Next Revolution in Industrial Manufacturing

The anticipated 3D printing boom has roots in a number of different industries. For example, the consumer electronics and automotive industries will represent a combined 40 percent of the coming growth. The medical device industry—spurred no doubt by the capability of 3D printing to produce mass customized finished goods—is set to account for 15 percent of that $21 billion market. Here are some additional highlights from the report:

- Two-thirds of manufacturers today already use some form of 3D printing. Twenty-five percent say they plan to adopt the technology in the future.

- The report cites the global manufacturing market as one “ripe for disruption” by 3D printing technologies. Want to know why? See Figure 2

- To date, the primary market for 3D printing includes printing systems, materials, supplies, and service and has grown at least 30 percent year over year from 2012 to 2014. Additional, robust growth comes from the secondary market—i.e., molding, castings, and tooling.

- Parts production is the fastest growing 3D printing application.

Figure 2. Source: 3D Printing: The Next Revolution in Industrial Manufacturing

Our team at HP finds that many enterprise leaders are intrigued by the possibilities of 3D printing and interested in exploring what the technology could bring to their business models. Not surprisingly, prototyping was the number one reason corporations cited for pursuing 3D printing. Innovation also made the list (16 percent). See Figure 3 below.

Figure 3. Source: 3D Printing: The Next Revolution in Industrial Manufacturing

Final Thoughts

The data above proves the 3D printing industry is poised for take-off, armed with the power to change how this generation of businesses approaches manufacturing. If everything from prototyping to mass producing is made exponentially quicker and more cost-effective than ever before, integrating 3D printing into business operations is a no-brainer. And there’s a less obvious benefit to 3D printing: It promises to equip entire industries with more potential to innovate, opening many exciting doors along the way. Can you imagine printing 3D objects from virtual worlds? It’s on the horizon.

At HP, we are honored to be able to work with manufacturers, co-developers, and strategic partners like Nike, BMW, Johnson & Johnson, Siemens, Autodesk, Protolabs, Materalise, Shapeways, and others to shape and transform the global manufacturing industry with 3D printing and are excited by all that’s happening and all that’s on the horizon for businesses of every kind.

What about you, and your industry? Can you pinpoint a fitting application for 3D printing in your organization? If it could streamline processes, improve your time to market and ultimately cut costs, would you take a chance on the technology? Let me know in the comments. I’d love to hear your thoughts.

This post was first published on LinkedIn.

Vincent Brissot is the Head of Channel Marketing & Operations at HP. With some 14 years of experience in channel enablement, business development, and marketing, he has a comprehensive understanding of and expertise in the IT industry related to hardware, services, and software. Vincent has worked in multiple countries, in regional and worldwide roles across Enterprise and SMB market segments. You can follow Vincent on Twitter @VincentBrissot and also find him on LinkedIn.

Vincent Brissot is the Head of Channel Marketing & Operations at HP. With some 14 years of experience in channel enablement, business development, and marketing, he has a comprehensive understanding of and expertise in the IT industry related to hardware, services, and software. Vincent has worked in multiple countries, in regional and worldwide roles across Enterprise and SMB market segments. You can follow Vincent on Twitter @VincentBrissot and also find him on LinkedIn.

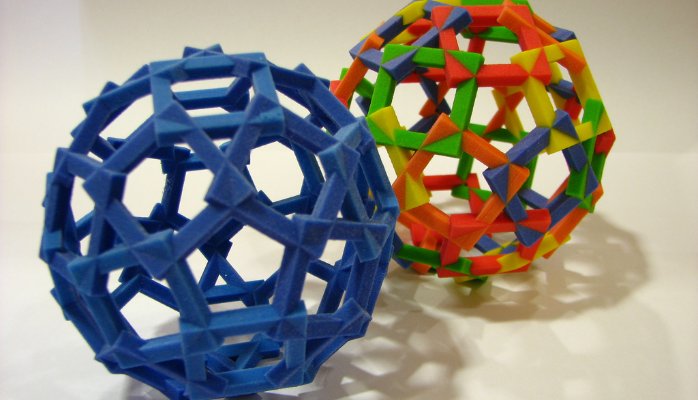

photo credit: 3D Printed Slide-Together via photopin (license)